Figuring out fracking

There's been a lot of talk about fracking in the past - but how does it really work and why do we do it?

- In this section:

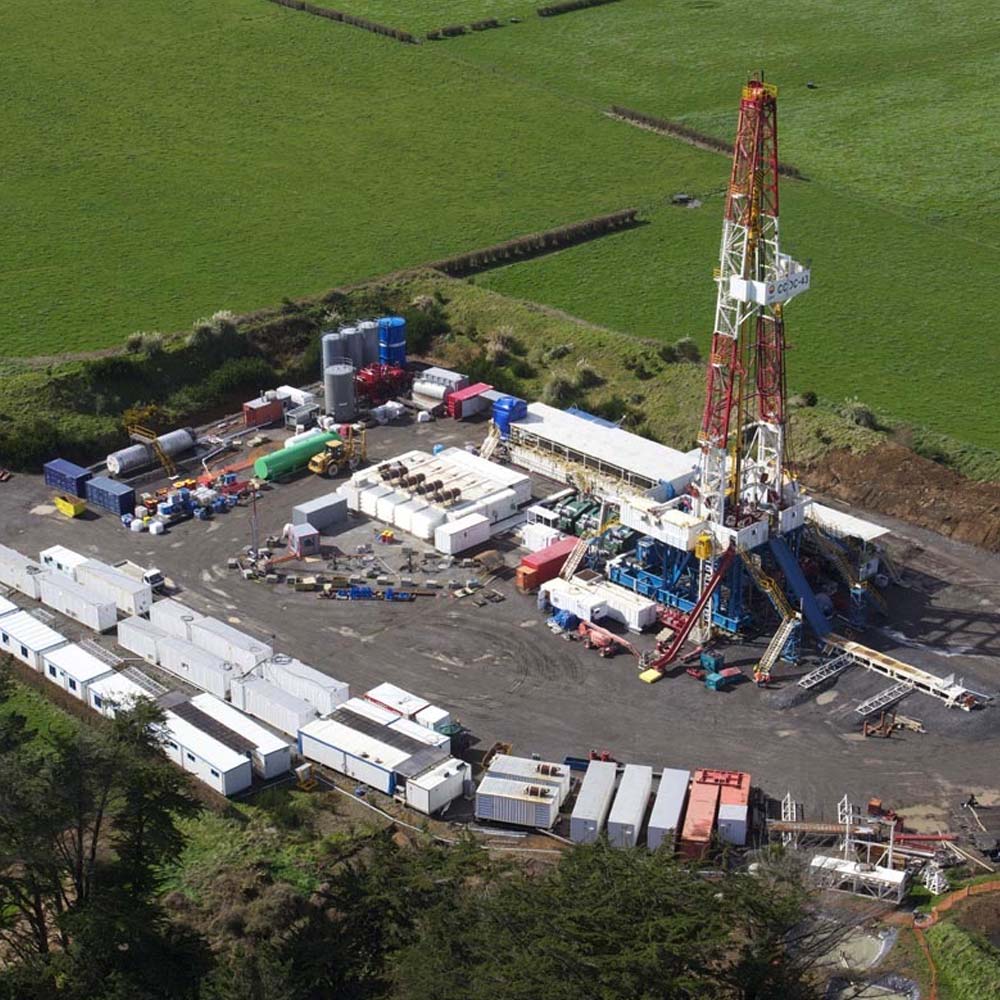

Hydraulic fracturing, or fracking, has been practiced around the world for decades but has gained a higher profile over the last 10 years with the oil and natural gas boom in the United States.

The first frack

1989

at Petrocorp's Kaimiro-2 gas well in Taranaki.

Almost all fracking has taken place in

Taranaki

but some fracks have occurred in Waikato and Southland.

There have been around

100

Fracks in total

Every frack is subject to

Resource Consent

approval and monitoring.

What is fracking?

1

Not all oil flows freely from a well. Sometimes oil and gas are trapped so tightly within the rock itself that it will not flow naturally to the surface. This is known as ‘tight’ oil or gas.

Hydraulic fracturing makes it possible to extract this ‘tight’ oil or gas from dense rock. The process injects water, proppant (sand or ceramic beads) and a very small proportion of chemicals into a well at high pressure. This creates small cracks in the rock, usually only a few millimetres wide. The proppant keeps the cracks open, creating channels the oil or gas can travel through to the well. Hydraulic fracturing is only effective with rock that has extremely low permeability (the ability of liquids or gases to pass through the rock).

A consent to Frack

2

Any fracking operation must go through the resource consenting process with the appropriate regional council to ensure all activity complies with regulatory oversight.

The resource consent application must be accompanied by an Assessment of Environmental Effects, which details the effect the activity may have on the environment. Included within the consent application is any request to source freshwater for the operation.

The Resource Consenting Process

Other approvals

Fracking fluid approval. Chemicals used in fracking must be approved by Hazardous Substances and New Organisms Act, which is implemented by Environmental Protection Agency (EPA). The approval will contain conditions for storage, transport, handling, labelling and disposal of chemicals.

Should we be fracking in New Zealand?

3

The Parliamentary Commissioner for the Environment (PCE), Dr Jan Wright, has released two reports that relate to the management of petroleum operations and the use of hydraulic fracturing in New Zealand.

As the PCE notes, The Royal Society of London concludes fracking can be managed as long as 'operational best practices are implemented and enforced through regulation'.

Bad press for fracking overseas

Fracking in the US and overseas is widespread, with thousands of wells being drilled by hundreds of operators.

Sometimes those wells fall outside industry best practice, are drilled to shallow depths, thus potentially compromising water tables, and haphazardly managed, leading to possible surface spillage and further contamination.

How is fracking in New Zealand different?

New Zealand companies drill far less wells (to date less than 100 fracks have occurred), and these take place in a very limited geographic area, under a comparatively stringent regulatory regime.

Wells in

NZ

Mainly vertical wells. 4-5 pumps. Up to 30 bbl/min. Sand reservoirs. Typically below 3000m.

Wells in

USA

Mainly horizontal wells. 20+ pumps. Up to 150 bbls/min. Shales and coals. Various 800m+ depths.

Four findings on fracking were made by the Parliamentary Commissioner for the Environment (PCE) on processes essential for good management of environment risks:

- Choose the well site carefully.

- Design and construct wells to prevent leaks.

- Prevent spills and leaks on the surface.

- Store and dispose of water with care.

The Ministry for the Environment guidelines 'Managing Environmental Effects of Onshore Petroleum Development Activities' (Including Hydraulic Fracturing) were released by the Government in response to the PCE’s interim report.

These guidelines are designed to ensure hydraulic fracturing is carried out in a robust, controlled and well regulated manner.

What are some concerns about fracking?

4

Fracking fluids - what are they?

The majority of fracking fluid is just water. And there's sand (or ceramic beads) in there, which holds the tiny cracks open once they have been made. Some additives are included, to help the water do it's job. Most of these additives are common chemicals, many of which you can find in your garage.

The chemicals used include:

- A friction reducer to make it easier to pump and evacuate fluid

- Natural plant-based gel to hold sand in place

- Gel management system to keep the gel stabilised while sand moves into fissures

- Clay stabiliser to prevent any clay in the reservoir rock from plugging the reservoir when it comes in contact with water

- Corrosion inhibitor to stop the well casing from corroding

- Bactericide to stop corrosion caused by bacteria

Like the chemicals used in many industries some of the additives used in hydraulic fracturing operations can be toxic to humans and/or the environment, particularly when they are in concentrated form – such as when they are being transported to the well-site. After being diluted, some additives may still be harmful to human health if ingested or if a person comes into direct contact with them, and to organisms in the environment.

Whether hydraulic fracturing fluids are harmful depends on what kind of additives are present, at what concentration, and whether they are released into the environment.

The Environmental Protection Agency (EPA) and/or local authorities strictly regulate the handling, storage, transport and disposal of chemicals and hydraulic fracturing fluids, requiring appropriate contingency plans to manage spills and discharges, should they occur. For example, resource consents can require the preparation of a contingency plan and ongoing monitoring and testing of local fresh water resources.

Flow back - salty water ('produced' water).

Along with the fracking fluid itself, highly mineralised salty water, known as 'produced water' can return to the surface and this can contain heavy metals and naturally occurring radioactive materials. This water must be separated and then stored and disposed of in accordance with regulations, primarily in lined pits or tanks. In New Zealand this salty water is mostly reinjected into an approved disposal well for long term disposal. There are no instances of this water migrating back into aquifiers.

Injecting requires resource consent under Resource Management Act (RMA) as 'discharge to land', including setting injection rates. There are six waste water injection sites in Taranaki that are consented for disposal of fracking fluids.

Contamination of aquifers

There has been plenty of publicity around fracking effecting water sources. Let's take a look at how that is technically highly unlikely.

Wells have up to four layers of thick steel casings, each layer cemented in place, forming a barrier against fluids ‘leaking’ into aquifers. Systems on the surface which manage pressure in the well during extraction also help ensure the potential for unplanned leaks is kept to a minimum.

The design, construction and operation of a well ensure well integrity. Well integrity is regulated by local authorities and WorkSafe.

In addition, hydraulic fracturing is typically used in shale and tight gas reservoirs which are usually very deep below aquifers. The reservoirs and aquifers are separated by impermeable layers of rock, called geological seals.

These rock layers stop oil, gas, drilling muds and hydraulic fracturing fluids from making their way to the surface.

The likelihood of petroleum or fluids reaching an aquifer through a fracture is extremely low. This is because of the vertical separation of the petroleum layer and the aquifer – which can be kilometres apart. The hydraulic fracturing activity is specifically designed so that the fractures remain inside the layer of petroleum-bearing rock.

Surface spillage and the water table. It's at the above ground storage point that possible spillage and site contamination can occur, either from fracking liquid, produced water, or from onsite chemical storage facilities.

Onsite regulatory requirements are required to account for this possibility.

To date no major fracking accidents have been reported in the Taranaki region.

Harm to Papatuanuku

For Maori, harming the mauri (life force) of the earth mother has spiritual implications and also endangers future sources of kai (food) and wai (water).

Some particular areas are sources of traditional mahinga kai for local Maori and tapu.

To that effect, regulation requires both government agencies and oil and gas companies to liaise with iwi at all key points of the field development process.

For more on the engagement process with iwi click the link below.

Does fracking start earthquakes?

Injecting fluids deep underground, through hydraulic fracturing or deep well injection, has been known to induce minor (micro) seismic activity in New Zealand.

According to GNS Science, seismic activity associated with hydraulic fracturing is generally less than magnitude 2.0. (A 2.0 shake can be described as felt only by a few people at rest in houses or on upper floors).

In 2012 GNS Science assessed seismic activity associated with hydraulic fracturing in the Taranaki region between 2000 and mid-2011. They found no evidence that hydraulic fracturing activities (including the deep well injection of waste fluids) in Taranaki had any observable effect on natural earthquakes of magnitude 2.0 or larger.

The study concluded that, at a depth of 2-4km, an earthquake of magnitude 2.0 is likely to produce surface vibrations similar to that caused by a nearby passing truck, but no more.

Before drilling begins, operators analyse geological information about fault lines in the area to assess whether any faults could generate earthquakes or permit fluids to pass between the petroleum reservoir and any shallower freshwater zones.

Records from earthquake monitoring systems (national and Mt Taranaki) show no evidence of fracking causing earthquakes felt on the surface.

Volumes of water used

Fracking uses between 100 and 350 cubic meters of water per frack (largest 2000 cubic meters).

As a comparison, an olympic swimming pool is measured at 2500 cubic meters.

Water is taken from ground or surface water onsite or town supply.

As New Zealanders continue to have a conversation around the utilisation of fresh water, we will need to decide on the relative merits of using fresh water for industrial production – for example in intensified dairying, horticulture, as well as oil and gas.

That said, comparative volumes of water used in standard fracking operations in New Zealand don't begin to approach water taken for the horticulture or dairy industries.

Climate change

Fracking a well generally releases a mixture of oil and gas. If the well is a predominantly oil sourcing well, the gas coming out in addition to the oil may be flared.

Flaring gas is considered better for the environment than the release of raw natural gas – which contains methane, a much more powerful greenhouse gas that CO2.

Flaring of gas as a practice is accounted for in the New Zealand's Emissions Trading Scheme.

Flaring also needs resource consent as it is a discharge of contaminants into air under the Resource Management Act (RMA). Regional councils consider proximity to people and contents of gas if vented and combustion products (if flared).